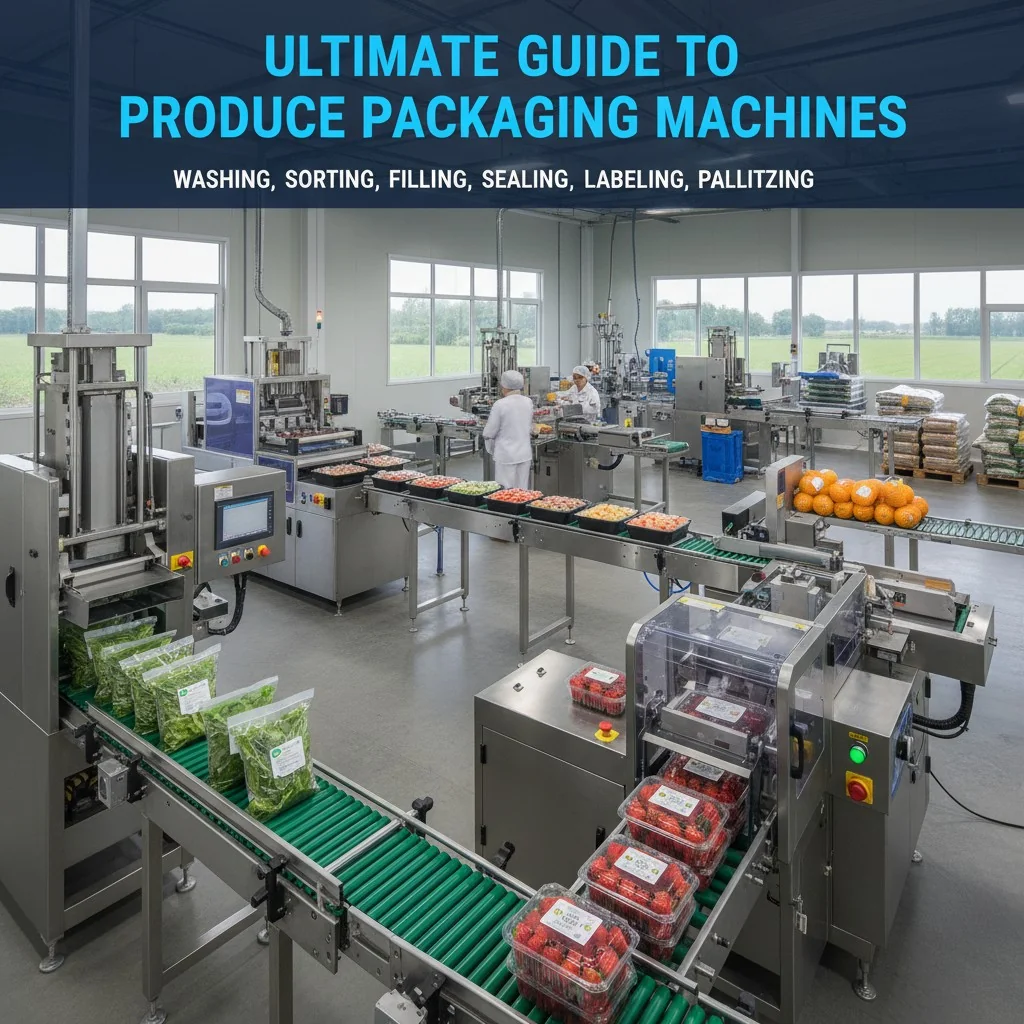

How Can You Choose the Right Produce Packaging Machine?

Struggling to find the right packaging solution for your products? The wrong choice can lead to damaged goods, high costs, and inefficiency. You need a system that fits perfectly.

Choosing the right produce packaging machine[^1] depends on your product, production volume, and desired shelf life. Key technologies include flow wrapping for individual items, thermoforming for custom trays, vertical bagging for loose items, and tray sealing for pre-formed containers. Each offers unique benefits for different needs.

I remember a client who was a large-scale vegetable grower. They were having trouble with their packaging line. The plastic trays they used were inconsistent, causing jams in their automated sealer. We traced the problem back to the mold design for the trays. It was a powerful lesson for me. The best packaging machine in the world can't fix a problem that starts with a poorly designed mold. Your product, your package, and your machine must all work together as one system. This guide will walk you through the different types of packaging machines, so you can see how everything connects, from the initial mold design to the final packaged product on the shelf.

All packaging machines can handle both rigid and flexible films.False

Different machines are specialized. For example, thermoformers typically use rigid or semi-rigid films for the base, while flow wrappers use flexible films.

Modified Atmosphere Packaging (MAP) can extend the shelf life of fresh produce by over 200%.True

By altering the gas composition inside the package (e.g., reducing oxygen and increasing carbon dioxide), MAP significantly slows down spoilage and maintains freshness.

What is Flow Wrapping and When Should You Use It?

Your individual products get damaged during shipping. This leads to waste and lost profits. You need a way to protect each item securely and efficiently.

flow wrapping[^2], or Horizontal Form-Fill-Seal (HFFS), is a process that wraps a product in a clear or printed film. It creates a sealed "pillow-pouch" with a fin seal on the bottom and seals on both ends. It's ideal for single items like broccoli or cabbage.

Flow wrapping is all about speed and presentation for solid items. I've seen it used for everything from single heads of broccoli to multi-packs of apples. The machine takes a roll of flat film, forms it into a continuous tube around the product, and then seals and cuts it. It’s incredibly efficient for high-volume production.

Key Considerations for Flow Wrapping

When you're thinking about flow wrapping, you need to consider the product and the film. The design of the package is critical.

| Factor | Description | Impact on Mold/Product Design |

|---|---|---|

| Product Shape | Is the product uniform or irregular? | Uniform products are easier to wrap. For product holders or trays, the mold must create a shape that feeds smoothly into the machine. |

| Film Type | Polypropylene, laminates, etc. | The film must be compatible with the product and provide the right barrier properties. The choice can affect the final look and feel. |

| Seal Integrity | Airtight seals are crucial for freshness. | The machine settings must be precise. Any inconsistencies in a tray or holder can compromise the seal. |

This method is great for giving each product a professional, branded look while offering protection.

Flow wrapping is only suitable for food products.False

Flow wrapping is widely used for non-food items as well, such as medical devices, hardware, and consumer goods, due to its speed and protective qualities.

Changing the product size on a flow wrapper requires several hours of mechanical adjustments.False

Modern flow wrappers often feature servo-driven controls and pre-programmable settings, allowing for product changeovers in just a few minutes.

How Does Thermoforming Shape Your Packaging and Your Costs?

Off-the-shelf packaging doesn't fit your product perfectly. This results in poor presentation and wasted material. You need a custom solution without the high cost of pre-made containers.

thermoforming[^3] creates custom-fit packaging by heating a plastic sheet and forming it into or around a mold. This process is perfect for creating trays, clamshells, and blisters that match your product's exact shape, reducing plastic use and cost.

This is where my world of mold design directly connects with packaging. A thermoforming machine is essentially a mini-factory. It takes a roll of plastic sheet, heats it until it's pliable, and then uses a mold to shape it. The quality of that mold is everything. I once worked with a client to design a thermoforming mold for a new line of snack packs. We spent weeks optimizing the draft angles and cooling channels. The result? They could run their machine 15% faster and cut their material waste by 10%.

Thermoforming: Mold Design is Key

The mold dictates the final package's quality, function, and cost.

| Aspect | Importance | Design Consideration |

|---|---|---|

| Material Distribution | Ensures uniform wall thickness. | The mold must be designed to stretch the plastic sheet evenly, avoiding weak spots, especially in deep corners. |

| Cooling | Affects cycle time and part stability. | Efficient cooling channels within the mold are critical to solidify the part quickly and prevent warping. |

| Air Vents | Allows trapped air to escape. | Tiny vent holes are needed to ensure the plastic forms tightly against the mold surface for sharp details. |

A great thermoforming mold leads to a great package and an efficient production line.

Thermoforming can only produce very thin, flimsy packaging.False

Thermoforming can use plastic sheets of various thicknesses, from thin films for blisters to thick sheets for durable trays and enclosures.

The mold for a thermoforming machine is typically made of wood.False

While prototype molds can be made of wood or 3D-printed plastic, production molds are almost always machined from aluminum for its excellent thermal conductivity and durability.

Is Tray Sealing the Key to Freshness and Presentation?

Your pre-packaged meals or produce lose freshness quickly. This leads to spoilage and unhappy customers. You need a way to seal in quality and extend shelf life.

tray sealing[^4] is a process that seals a pre-formed tray with a layer of flexible film. It's often combined with Modified Atmosphere Packaging (MAP) to extend shelf life, making it ideal for fresh-cut produce, salads, and ready-to-eat meals.

Tray sealing is a fantastic solution for presentation and preservation. You start with a tray, which could be a thermoformed part we just discussed. You fill it with your product, and the machine takes over. It places the tray in a chamber, often flushes out the regular air and replaces it with a special gas mix (MAP), and then heat-seals a film lid on top. This process is what keeps salads crisp and meat fresh for days longer. The key here is consistency. The trays must be uniform, with a perfect flange for the film to seal against. Any defect in the tray mold will show up as a failed seal down the line.

Achieving the Perfect Seal

The success of tray sealing depends on the harmony between the tray, film, and machine.

| Component | Role | Critical Factor |

|---|---|---|

| Tray | Holds the product. | The tray's top flange must be flat and free of defects. The mold design is crucial for creating this perfect sealing surface. |

| Film | Creates the lid and barrier. | Must be compatible with the tray material (e.g., PP, PET) to create a strong, peelable seal. |

| Machine | Applies heat, pressure, and time. | The sealing head must provide uniform temperature and pressure to ensure the entire rim of the tray is sealed securely. |

When all three work together, you get a secure, attractive package that preserves your product.

Tray sealing is a slower process than flow wrapping.True

Generally, tray sealing involves multiple steps (placing tray, filling, sealing) and often includes a vacuum/gas flush cycle, making its per-unit cycle time longer than the continuous motion of flow wrapping.

Any plastic tray can be used with any sealing film.False

The tray material and the sealant layer of the film must be compatible. For example, a PP (polypropylene) tray requires a film with a PP sealant layer to create a proper weld.

Why is Vertical Bagging a Go-To for Bulk Produce?

Bagging loose items like potatoes or nuts is slow and inaccurate. This causes production bottlenecks and inconsistent package weights. You need a fast, automated solution for bulk products.

Vertical Form-Fill-Seal (VFFS) machines create bags from a roll of film, fill them with product from above, and then seal them. They are extremely fast and are often paired with multihead weighers for accuracy, making them perfect for loose items.

When you think of a bag of chips or a bag of frozen peas, you're thinking of a VFFS machine. I find these machines fascinating. A flat roll of film is fed up and over a forming tube, which shapes it into a cylinder. The machine then makes a vertical seal down the back and a horizontal seal at the bottom, creating an open bag. The product, which has been precisely weighed, drops in. Then, the machine makes the top seal, which also forms the bottom seal of the next bag, and cuts it free. It's a continuous, high-speed dance of forming, filling, and sealing. It’s the workhorse for any product that can be dropped, from salad mixes to hardware parts.

The VFFS Process Breakdown

It's a simple concept with powerful results for efficiency.

| Step | Action | Key Technology |

|---|---|---|

| 1. Film Unwinding | A roll of film is pulled into the machine. | Dancer arms maintain proper film tension. |

| 2. Bag Forming | Film is shaped into a tube by a forming collar. | The design of the forming collar is critical for bag shape. |

| 3. Filling | Product is dropped from a weigher or doser. | Often paired with a multihead weigher for accuracy. |

| 4. Sealing & Cutting | Heated jaws seal the bag horizontally and cut it. | The jaws create the top seal of one bag and the bottom of the next. |

This process is the backbone of packaging for countless bulk products.

VFFS machines can only create 'pillow' style bags.False

With different forming collars and jaws, VFFS machines can also create other bag styles, such as gusseted bags, block-bottom bags, and quad-seal bags for better shelf presentation.

The speed of a VFFS machine is limited by how fast a person can manually load the product.False

VFFS machines are almost always integrated with automated fillers, like multihead or auger fillers. The speed is typically limited by the product itself or the sealing time, not manual loading.

Could Stretch Wrapping Be the Simplest Solution for Your Products?

You need a simple, low-cost way to wrap fresh produce on trays. Complex machines are too expensive and slow for your needs. You want a quick and clear packaging method.

stretch wrapping[^5] uses a highly elastic film that is stretched around a product, often on a tray. The film's elasticity keeps it tight, providing a clear, secure covering. It's a very common method for packaging fresh meat and produce in supermarkets.

Stretch wrapping is simplicity at its best. Think about the packaged mushrooms or asparagus you see at the grocery store. That's usually stretch wrap. The product is placed in a tray—again, a part that likely came from a thermoforming mold—and a machine or a person pulls a thin, stretchy film over it. The film clings to itself and the tray, creating a tight, transparent cover. While there are large, automated stretch wrappers for palletizing goods, for individual produce items, it's often a semi-automatic process. It doesn't offer a hermetic seal like tray sealing, but it's fast, cheap, and great for products that need to breathe or have a short shelf life.

When to Choose Stretch Wrapping

It's not for every product, but it excels in certain situations.

| Advantage | Disadvantage | Best For |

|---|---|---|

| Low Cost | Film and machinery are inexpensive. | Not an airtight seal, so shelf life is limited. |

| High Clarity | Excellent product visibility. | Offers minimal physical protection. |

| Breathability | Allows for gas exchange. | Not suitable for Modified Atmosphere Packaging (MAP). |

For fast-moving fresh items like individual cabbages or broccoli on a tray, stretch wrapping is a very practical choice.

Stretch wrap and shrink wrap are the same thing.False

Stretch wrap is stretched to wrap a product and stays tight due to its elastic recovery. Shrink wrap is loosely applied and then heated, causing it to shrink and conform tightly to the product.

Stretch wrapping provides a hermetic (airtight) seal.False

Stretch wrapping does not create a hermetic seal. It is permeable to air and moisture, which is why it's often used for fresh produce that needs to 'breathe'.

When Does Full Line Automation Become a Necessity?

Your production is growing, but manual processes are creating bottlenecks. Labor costs are rising and consistency is suffering. You need a more integrated and efficient system.

full line automation[^6] connects multiple packaging machines—like weighers, baggers, and case packers—into one seamless, synchronized system. It becomes necessary when high volume, speed, and consistency are critical, and you need to reduce manual labor and human error.

I've seen companies transform their business with full line automation. It's a big step. It’s not just about buying one machine; it's about designing a whole system. Imagine produce coming in on a conveyor, being weighed by a multihead weigher, dropped into a bagger, then the bag is checked, placed into a box by a robot, and the box is sealed and palletized. No human hands touch the product after the initial loading. This is the goal of full automation. Companies like Xiamen XiaoSen Packaging specialize in this, offering everything from single components to these highly complex, fully integrated lines. It’s a major investment, but for large-scale producers, the return in efficiency and quality is massive.

Building an Automated Line

It's about connecting specialized machines to work as one.

| Stage | Machine Example | Function |

|---|---|---|

| Infeed | Conveyor System | Transports raw product to the line. |

| Weighing | Multihead Weigher | Accurately portions the product. |

| Packaging | VFFS or Tray Sealer | Places the product into its primary package. |

| Inspection | Checkweigher / Metal Detector | Ensures package weight is correct and free of contaminants. |

| Secondary Packaging | Case Erector / Robotic Packer | Places finished packages into shipping cases. |

| End of Line | Palletizer | Stacks cases onto a pallet for shipping. |

This level of integration is the future for high-volume manufacturing.

Full line automation is only for very large, multinational corporations.False

While the investment is significant, modular and scalable automation solutions are becoming more accessible for mid-sized companies looking to automate specific parts of their line.

Once an automated line is set up, it never needs human oversight.False

Automated lines require skilled operators for monitoring, quality control, maintenance, and changeovers. The nature of the work shifts from manual labor to technical oversight.

How Do Multihead Weighing, Loading, and Batching Boost Accuracy?

You're giving away product with every overweight bag. Your manual portioning is slow and inconsistent. This directly eats into your profit margins on every single package.

multihead weighing[^7] uses multiple weighing buckets to calculate the perfect combination to hit a target weight with incredible accuracy. Paired with automated loading and batching, it ensures minimal product giveaway and consistent package weights at high speeds.

The multihead weigher is one of the most brilliant pieces of engineering on a packaging line. I love watching them work. The product is fed to the top and distributed into a dozen or more small buckets, each holding a fraction of the target weight. A computer then instantly calculates which combination of those buckets adds up to the exact target weight. It then opens just those buckets, dropping a perfect portion into the bagger or tray below. The process is incredibly fast and reduces "giveaway"—the extra product you put in each bag to be safe—to less than a gram. For a company producing millions of bags a year, that tiny saving adds up to a fortune.

The Magic of Combination Weighing

This technology is all about speed and precision.

| Component | Function | Benefit |

|---|---|---|

| Dispersion Cone | Vibrates to distribute product evenly to the feed buckets. | Ensures all weigh buckets receive product. |

| Feed Buckets | Hold a small amount of product. | Portions the product for the weigh buckets. |

| Weigh Buckets | Each bucket contains a load cell to weigh its contents. | Provides the individual weights for the computer. |

| Computer | Calculates the best combination of weights. | Finds the combination closest to the target weight in milliseconds. |

This system is essential for profitability when packaging any bulk product where weight matters.

Multihead weighers are only for dry, free-flowing products like nuts or candy.False

There are specialized multihead weighers designed for sticky products (like gummies or fresh chicken) and fragile products (like crackers or leafy greens), using different bucket coatings and gentler handling.

A multihead weigher can only handle one product type.False

Modern multihead weighers can store dozens of product programs. An operator can switch from weighing carrots to weighing nuts in minutes by selecting a new program on the touchscreen.

i

Choosing the right packaging machine is vital. From flow wrapping to full automation, each technology serves a purpose. Understanding them ensures your product, package, and process work together perfectly.

Referencias

[^1]: Explore expert insights on choosing the right produce packaging machine to enhance efficiency and reduce costs.

[^2]: Learn about flow wrapping technology and its benefits for packaging individual items efficiently.

[^3]: Discover how thermoforming creates custom-fit packaging that reduces waste and enhances product presentation.

[^4]: Find out how tray sealing preserves freshness and improves the presentation of pre-packaged meals.

[^5]: Explore the simplicity and effectiveness of stretch wrapping for fresh produce and its cost benefits.

[^6]: Learn how full line automation can streamline production processes and enhance efficiency in packaging.

[^7]: Discover the technology behind multihead weighing and its impact on reducing product giveaway.