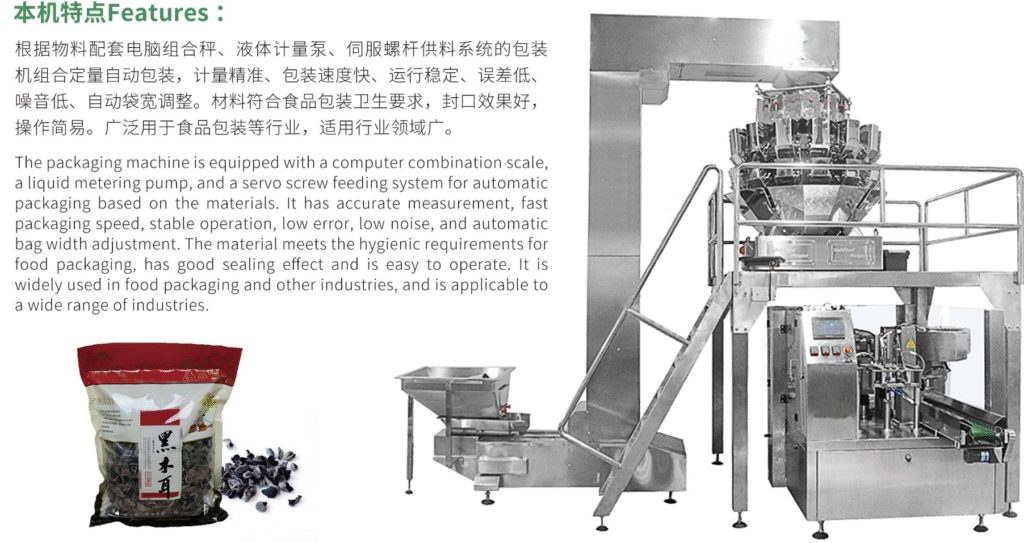

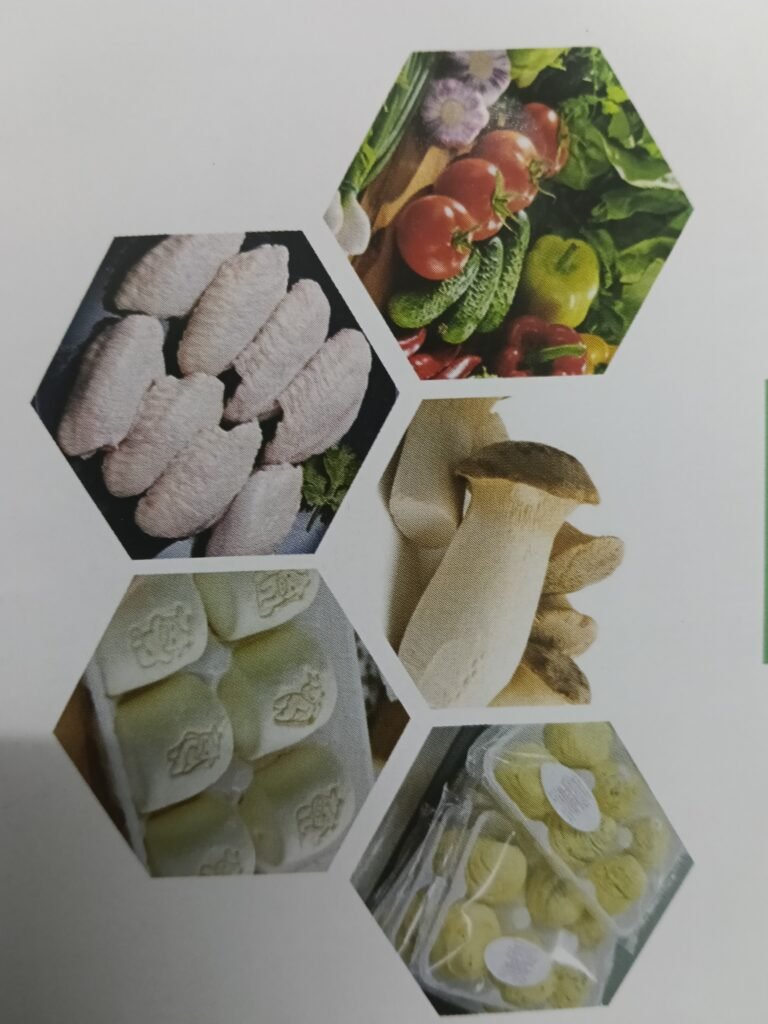

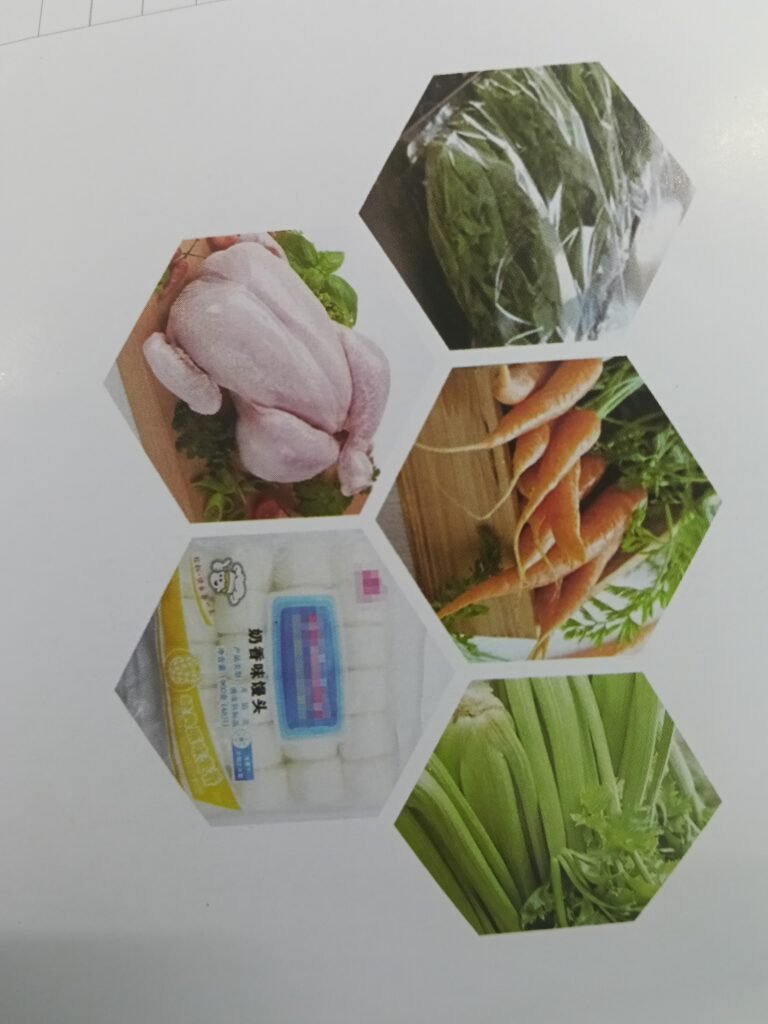

Extended Shelf Life –

Specialized films and trays keep salads, 채소, and pre-sliced produce fresher for longer by reducing moisture loss and contamination.

Ready-to-use

Packaging makes healthy eating easier, offering grab-and-go solutions that fit modern lifestyles.

Sustainability & Safety –

Recyclable, food-safe packaging materials support environmental goals while maintaining product quality and protection.